How are Polypropylene Carpets made?

When shopping for carpets, you’ve probably come across the term polypropylene. But what exactly does that mean, and how are polyprop carpets made? Polypropylene carpets are one of the most popular synthetic flooring options thanks to their durability, stain resistance, and affordability. Let’s break down their composition and take a peek into the fascinating process of how they’re created.

What Is Polypropylene?

Polypropylene is a thermoplastic polymer — essentially, a type of plastic that can be melted and reshaped. It’s made from the polymerization of propylene gas, a by-product of petroleum refining. Because of its strength, lightweight properties, and resistance to moisture, polypropylene is widely used not just in carpets but also in packaging, automotive parts, and textiles.

Composition of Polypropylene Carpets

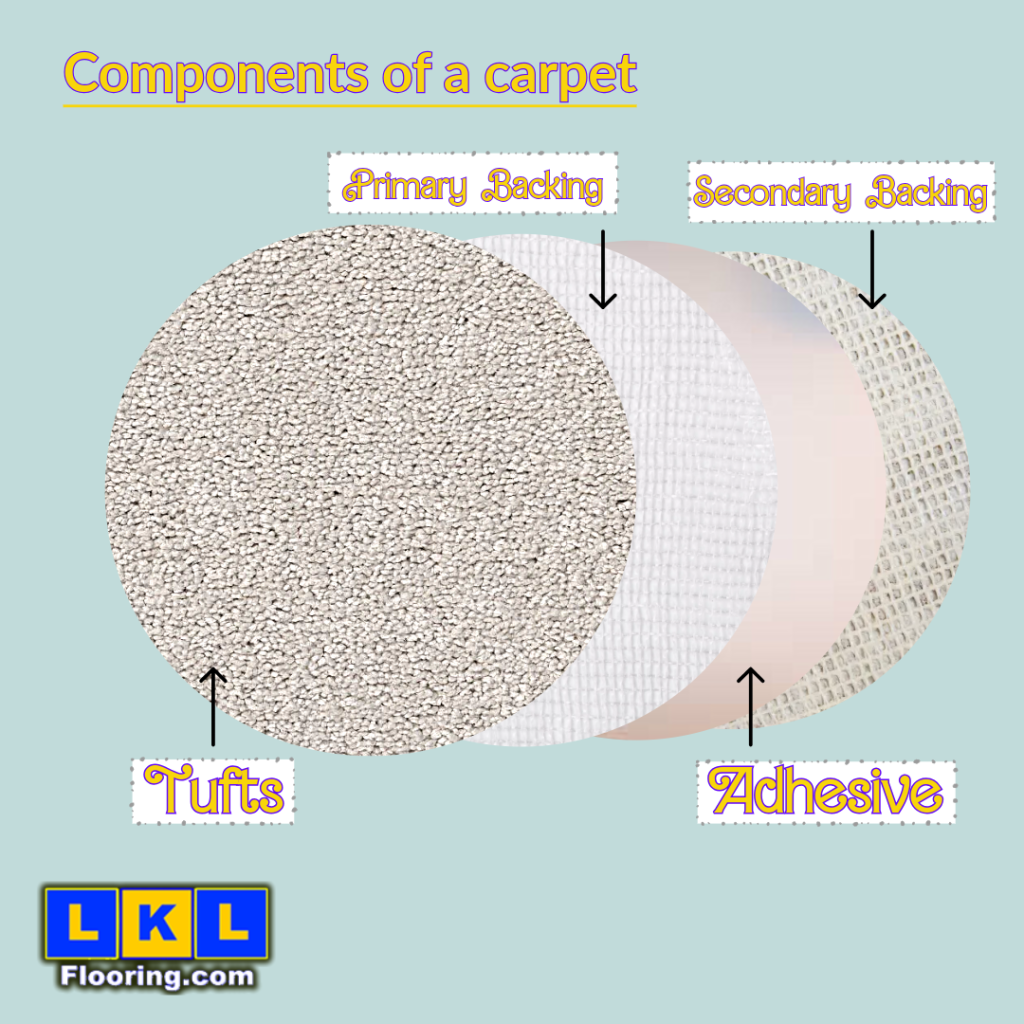

Polypropylene carpets are made almost entirely from synthetic fibers. The main components include:

- Polypropylene fibers: The primary material, spun into continuous filaments or staple fibers.

- Dyes & pigments: Polypropylene is usually solution-dyed, meaning the color is added to the polymer before the fibers are even formed. This makes the carpet resistant to fading.

- Backing material: Typically jute or synthetic latex, providing structure and grip.

- Binders & adhesives: Used to hold the fibers and backing together.

How Polypropylene Carpets Are Made

The manufacturing process follows several steps:

- Polypropylene pellets are melted, then forced through a metal mesh, with small holes to create yarn.

- Drawing & Spinning These yarns are stretched and twisted to add strength, then bundled together to create the tufts.

- Dyeing (Solution-Dyed) Since the color is added before mesh process, polypropylene carpets have excellent colorfastness and resist stains.

- Tufting or Weaving The yarn is stitched into a backing fabric using tufting machines (the most common method) or woven into intricate patterns.

- Backing & Finishing A secondary backing (often latex) is applied to stabilize the carpet and give it structure. The surface may also be sheared for smoothness.

- Inspection & Cutting When its finished the rolls are inspected for defects, trimmed, and prepared for shipping.

This video from you tube creator TheFBIfiles man, gives you a short video on how carpets are made. [CLICK HERE] Its very informative.

Why Choose Polypropylene Carpets?

- Stain resistant: Great for homes with kids or pets.

- Affordable: Typically less expensive than wool or nylon carpets.

- Moisture resistant: Doesn’t absorb water, making it ideal for all areas.

- Colorfast: Colors remain vibrant even in sunlight.

Of course, they can flatten under heavy furniture and are less heat resistant compared to wool or nylon. Still, for many households, they strike the perfect balance of cost and practicality.

We tend to showcase a polypropylene carpet for our stair runners in a loop pile. Primarily due to the robust qualities. See some of the options that we have available HERE.

Final Thoughts

Polypropylene carpets are a modern flooring solution born from clever chemistry and advanced manufacturing. By turning a simple plastic polymer into durable, colorful fibers, manufacturers have created a carpet that’s practical, stylish, and budget-friendly.